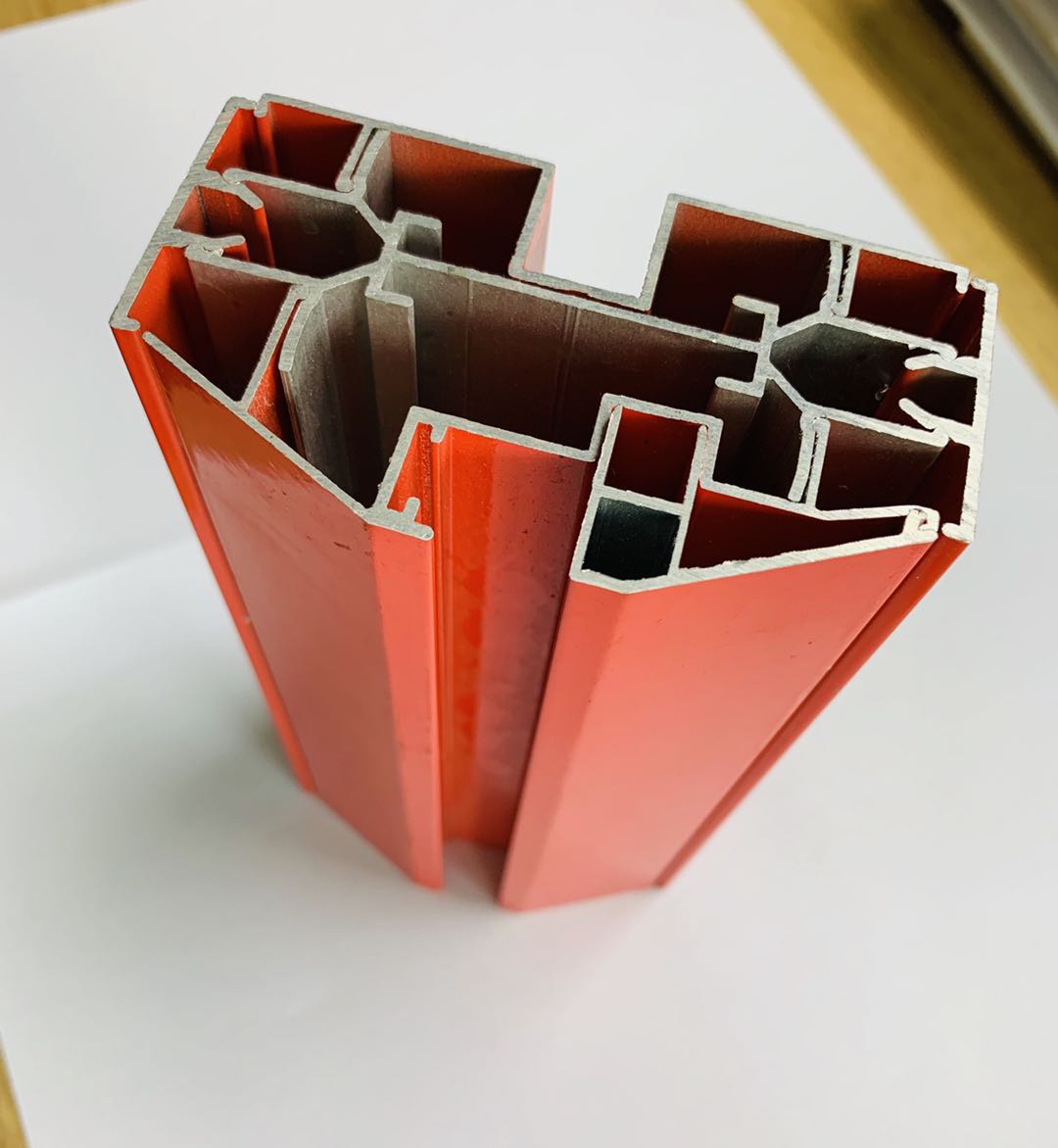

Simply put, aluminum extrusion is the aluminum alloy into the extrusion cylinder and exerts a certain pressure. So that it flows out from the specific die hole, to create aluminium profiles of fixed cross-sectional profiles. This method is efficient, low-cost, and handy. From another perspective, the principle of aluminum extrusion is like squeezing toothpaste.

But easier said than done. Nowadays all aluminium manufacturers are looking for methods of making production higher efficient, not only to improve the speed of extrusion, but also to extrude more profiles by only one die. In this article, we are going to talk about the manufacturing technique and quality control for mill-finishing aluminium extusion profiles.

5 tips for checking if there are quality flaws of mill finishing

Due to the particularity of the production process, the surface defects of aluminium profiles can be caused by polishing of the die or processing condition, like rough surface, low surface gloss or irregular.

After loading the die into the extruder, check 2-3 aluminum rods and then collect the samples. If the surface is qualified, then check the other items.

-

Touch the surface after cooling

Touch the surface of the mill finished profiles or try to use fingernails to dig the extrusion lines, try to feel the concave and convex, to see if there is any noticeable feel.

-

Pencil scratching

During the aluminium extrusion process, use a pencil to draw curves. Extruded aluminum products are made by forcing heated aluminum billets through a mold to produce the desired cross section. By using a pencil to determine whether there is a rough line. It is also a good way to check anodizing aluminum profiles.

-

Spray paint

Spray the surface of mill finishing aluminium profiles with spray lacquer. After 1-2 minutes, the paint dried, observe and check whether there is a line, concave, convex or other defects. Applicable to the surface inspection before powder coated.

-

Alkali washing test.

After squeezing 3 aluminium bars, cut 300mm as a sample, soak in the alkali liquor for 30-40 seconds. (Please notice the concentration of the lye and the temperature in the tank). If the concentration or temperature is too low, have to prolong the soaking time, make sure less than 60 seconds. After that, if color separation, die line or extrusion lines emerge, that will indicate defect level of the mill finishing aluminum profiles.

-

Surface polishing:

Take a scouring pad to polish on a 300mm of aluminum extrusion profiles in horizontal way. It is much easier to observe mass defect on the surface after grinding. It is used to check the thin lines, a good way to judge the quality of PVDF coating.

How to optimize aluminum extrusion?

As per aluminum extrusion, the most critical thing is the temperature. Because it will impact the quality, production efficiency and the lifespan of dies.

From ingot heating, to quenching of aluminum extrusion, need to avoid granulum separate out. The 6063 series aluminum ingot is mainly made of “Silicon”, “Magnesium” and “Aluminum”. Generally speaking, the heating temperature of 6063 aluminum alloy profile ingot is: 430℃-480℃ (Homogenized). With the extrusion process, the extrusion temperature increases gradually with the extrusion speed. To prevent the appearance of cracks in the aluminum profile, the extrusion speed should gradually decrease with the increase of temperature. The extrusion speed of the aluminum profile depends on the different geometry and cross-section, as well as the surface of mill finishing.

In recent years, liquid nitrogen has been used to cool mold, thereby increasing the rate of extrusion. In the extrusion process, nitrogen is squeezed to the exit of the extrusion die, which can make the cooled product shrink rapidly, cooling the extrusion die and the metal in the deformation area, so that the heat of deformation is taken away. At the same time, the exit of the die is controlled by nitrogen, which will reduce the oxidation of aluminum, and reduce the adhesion and accumulation of alumina. Therefore, nitrogen improves the surface quality of aluminum products and improves the extrusion speed.

The quench of 6063-T5 is to rapidly cool Mg2Si in matrix metal to room temperature after it is discharged from die hole at high temperature. The minimum cooling rate of 6063 aluminum alloy profile is 38℃/ min. Therefore, it is suitable for air cooling quenching.

After the aluminum profile comes out of the die hole, use the tractor to pull. When the tractor works, it gives traction tension to the extruded aluminum products and moves synchronously with the outflow speed of the products. The purpose of using the traction machine is to reduce the length of aluminum extrusion uneven and can prevent the aluminium profile twisting and bending out of the die hole.

How to prevent low hardness of aluminium profiles?

The hardness of extruded aluminum profile is too low to use before aging. Usually, aging can be divided into natural aging and artificial aging. At present, the production of 6 series aluminum profiles is based on the latter.

- Before extrusion, the temperature of the ingot should be measured to meet the technical requirements before production.

- At the outlet of the extruder, the quenching process should be selected according to the ingot species, thickness of aluminum profiles, extrusion speed and quenching equipment condition.

- Setting and control of aging furnace temperature: Set the time based on the temperature in aging furnace and pay close attention to the fluctuation of aging furnace temperature.

- Soaking time should be appropriate to prevent over-aging resulting in insufficient hardness.

- After extrusion, it cannot be too dense in the frame. There should be spacing between the aluminum, especially between the small and thick materials. Regarding the tube and angle are assembled in one frame, the tube should be put below, which is conducive to the aging cycle air supply.

- Aluminum profiles with special requirements need to be aged separately.

Causes of oil stain and water spot on the surface of aluminum profiles. How to avoid them?

Before the aluminum profile aging, if the oil stains are not wiped clean, then after aging, the aluminum surface will give rise to watermark, and there will be dark spots after oxidation.

Causes of oil/water marks on the surface of aluminum profiles:

- When sawing, oil stains are left at both ends of the aluminum profile, and the gloves are not clean or stuck with graphite ash when moving (lifting) the aluminium product

- The aluminum gets hydraulic oil when it is stretched

- Oil leakage from extruder

- The surface of aluminum profile is partially stained with water and rain

How we avoid this situation while producing?

- In the process of aluminum production, gloves should be clean when moving aluminum products, and oil stains should be wiped off in time

- Check extrusion, sawing and aligning machines regularly

- Keep the mat clean

- The aluminum profile with water should be dried immediately before aging. If the surface of the aluminum profile has turned black, alkali washing can be carried out

Ultimately, the most important thing for aluminum extrusion factory is to cultivate good operating habits and quality mind the employees.

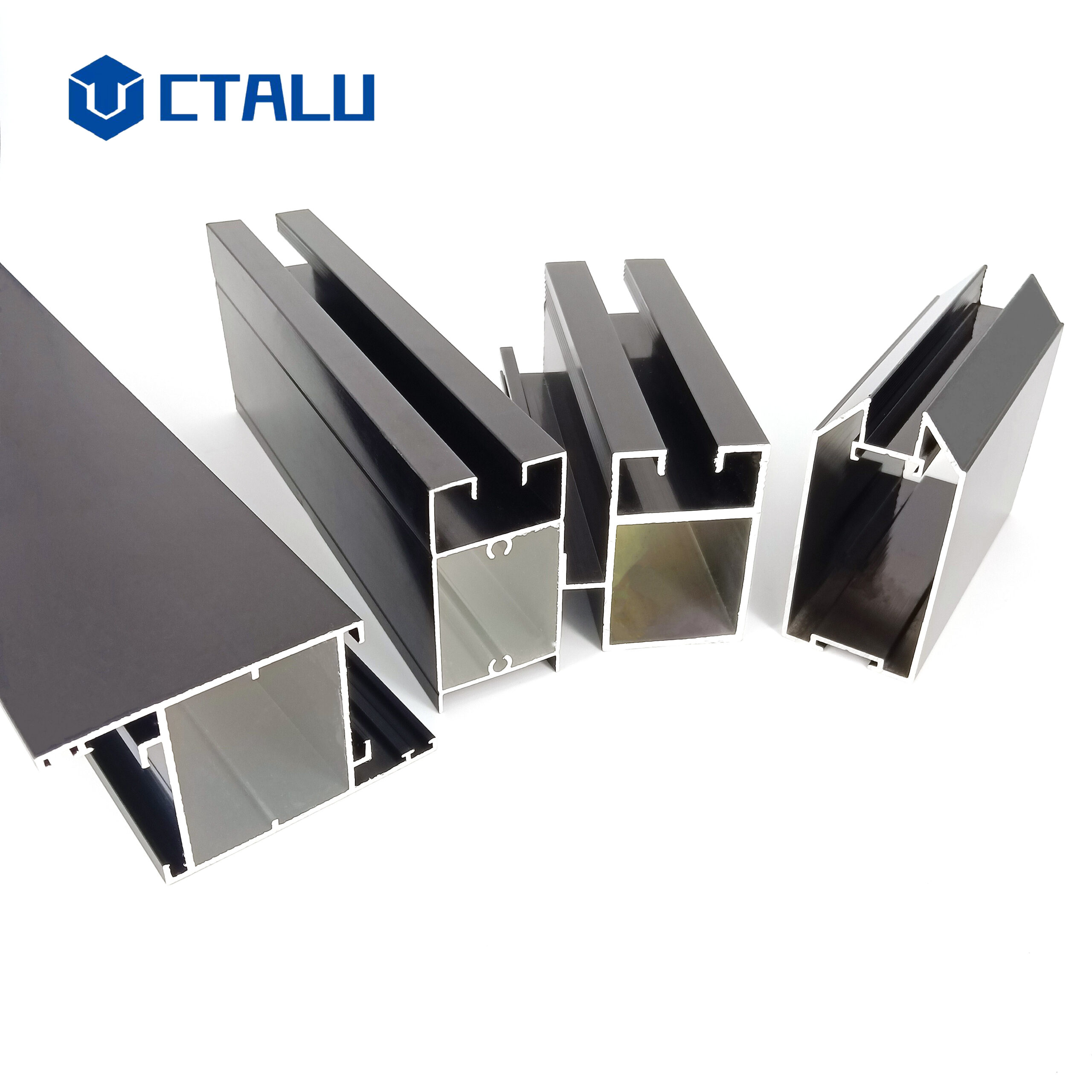

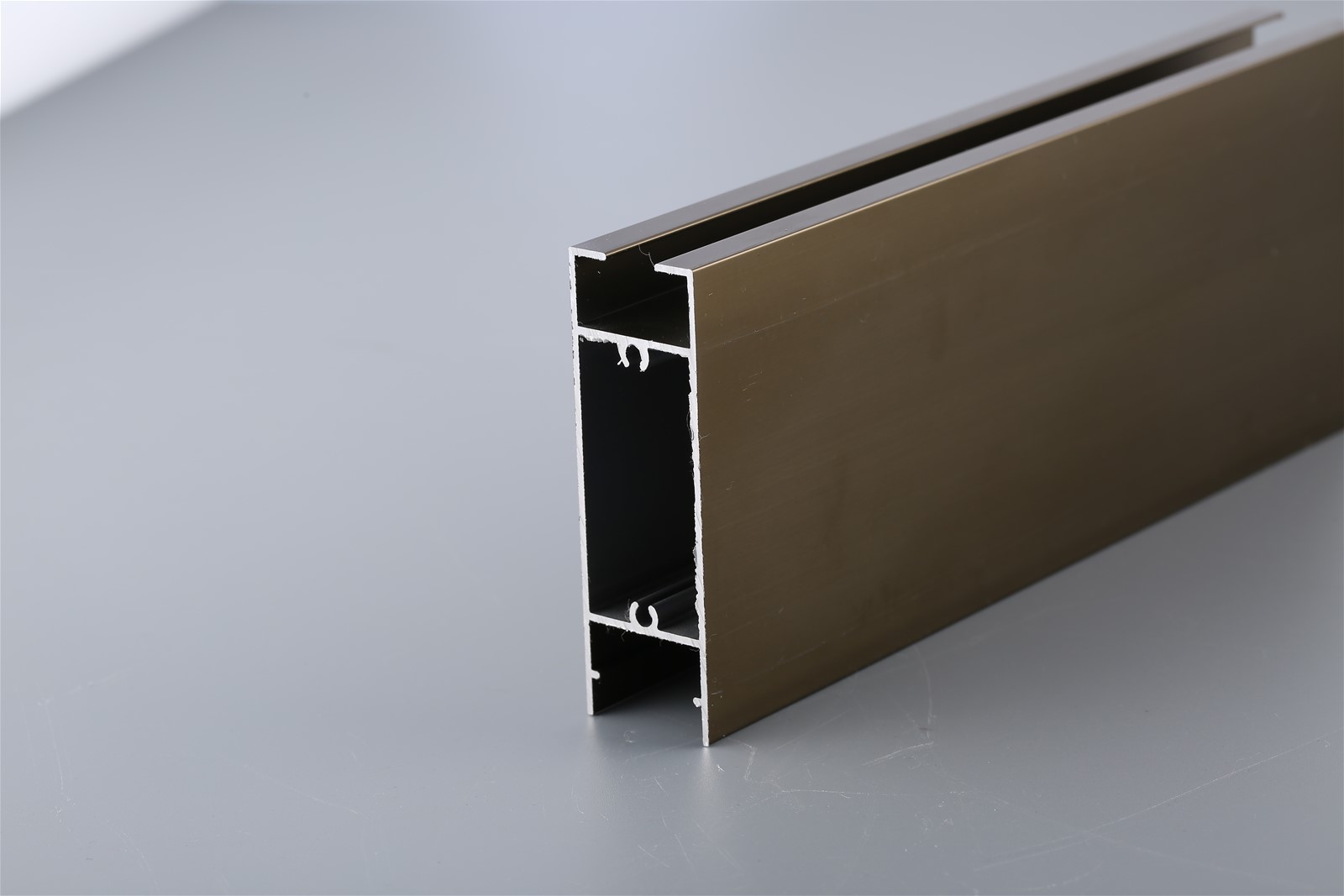

Cheetah Aluminum has a complete aluminum profile production line, from mill finishing, to any kind of surface treatments, such as anodizing profiles or powder coated profiles, wood grain or electrophoresis.

We insist on the use of standard aluminum alloy production, firmly do not use low quality powder. For decades, the surface technology of aluminum profiles has been constantly updated. If you need additional insight, our aluminum experts and designers can help you decide the best design, surface finish and temper needed to achieve your goals at a cost competitive, best extrusions fit within your budget.

Any questions please contact or inquiry, please feel free to contact:

Email: simon@ctalu.com