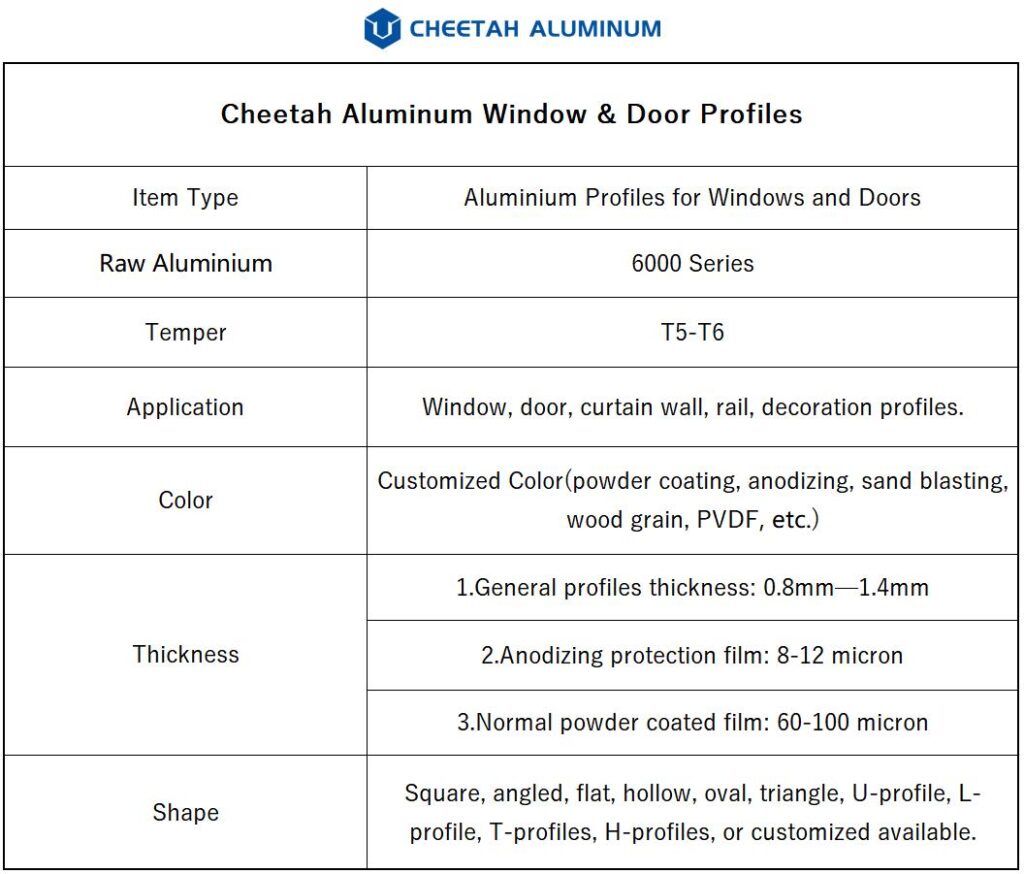

Doors and Windows have become an essential part of our lives as an important part of a house. Cheetah Aluminum used high-quality raw aluminium ingot to make aluminium windows and doors. Cheetah Aluminum International Co., Ltd. As a professional manufacturer of aluminium profiles for windows and doors, offers all types of customized designs to produce based on customers’ specific details.

When it comes to windows and doors, many raw materials come to mind, including wood, PVC, plastic steel, stainless steel, and aluminium extrusion profile.

Why Are Aluminium Extrusion Profiles a Better Material for Windows and Doors?

-

function of doors & windows

- Doors and windows should have heat preservation, heat insulation, sound insulation, waterproofing, and fire prevention functions. The new requirement: energy conservation, which refers to heat lost through windows and doors in cold areas, accounts for 25% of total heat consumption. Airtight requirements for doors and windows are an important part of the design. Windows and doors are critical components of a building’s structural system.

- Because doors and windows are an important part of architectural modeling (virtual and real contrast, artistic effect), their shape, size, proportion, arrangement, color, and modeling have a significant impact on the overall modeling of the building.

- Many people are now installing double-layer insulated glass doors and windows, which not only improve insulation but also sound insulation.

-

Comparison of various door and window materials

Wood: Wooden doors and windows are easier to process and repair. However, solid wood is easily deformed, and high-quality wooden Windows are made of synthetic wood.

Steel: Steel windows are strong, long-lasting, and fireproof. However, it is relatively easy for acidic gases in the air to corrode it. Steel windows have poor thermal insulation performance.

Stainless steel: Stainless steel doors and windows are attractive and will not rust. However, the cost is prohibitively expensive.

Plastic steel: Plastic steel doors and windows have a higher overall performance and are more cost-effective. However, the service life of the model steel door’s window is limited.

Aluminium: Aluminium doors and windows frames are the most beautiful of all materials due to their extrusion into aluminium profiles, modeling and color, and high performance. Aluminium doors and windows, on the other hand, have poor insulation and a high energy consumption.

Which Aluminium Alloy Is the Best Choice?

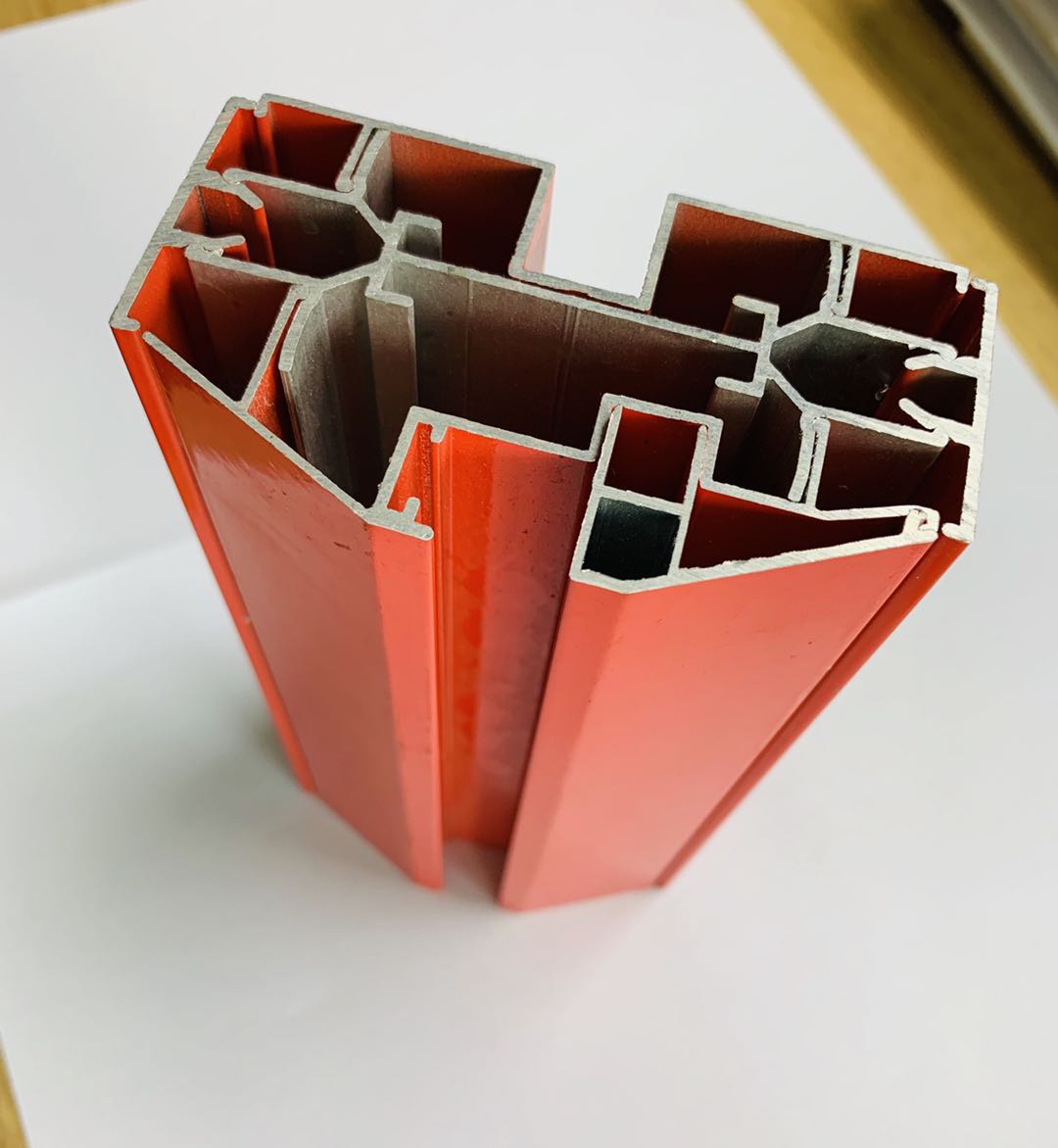

Aluminium alloys are widely used in the construction, aerospace, sporting goods, electrical, and automotive industries. Aluminium profiles for windows and doors are made from a variety of aluminium grades.

The 6000 series, which includes the following grades, is the most appropriate and widely used for windows and doors:

-

6061 Aluminium

Alloy 6061 has a high tensile strength that can be increased by tempering, as well as good corrosion resistance, weldability, and workability. Its workability makes it an excellent choice for many extrusion projects because it is simple to form.

When compared to other grades in the 6000 series, the 6061 grade has slightly lower strength. Furthermore, it has a wide range of mechanical properties that allow for incredible forming capabilities.

This aluminium grade is extremely machinable, weldable, and cold-workable. You can also use heat treatment, which provides suitable joining characteristics.

-

6063 Aluminium

A 6000 series member, 6063 is the most common in aluminium window and door framing. This alloy is the cheapest and has the lowest ultimate strength. However, it is very easy to extrude and has the best surface treatment. Dropped the strength issue, 6063 alloy is the autofit one for aluminium window and door sections.

After surface finishing, 6063 alloy has high corrosion resistance for window and door applications. It is lightweight and has excellent weldability and workability.

Assembly of Aluminium Window and Door Profiles

-

Screwed

This method of installation is quite popular because it involves the use of screws to secure the aluminium windows and doors. We can also use screws for window sills and jambs. This promotes the collaboration.

-

Interlocker

Interlocker is commonly used in the frame of a sliding window. It goes with the lock stile in the overall window combination. This is a clever and efficient method of connecting the window systems.

-

Corner bracket

This is also a common combination. Corner brackets are commonly available in plastic and aluminium. Corner brackets of various materials are used depending on the design of various aluminium doors and Windows framing. Plastic corner sizes are reasonably priced. We insert the corner bracket into the hollow aluminium profile after we cut the aluminium door and window bracket 45 degrees.

-

Hinge

The hinge is a component of the aluminium casement window. The hinge was an important component of the window. One casement window sash requires two hinges. Stainless steel is used for the hinges. We require that the hinge thickness be no less than 2.5mm in order to make the aluminium doors and windows more stable.

5 Points Need to Be Considered Before Placing Your Order

-

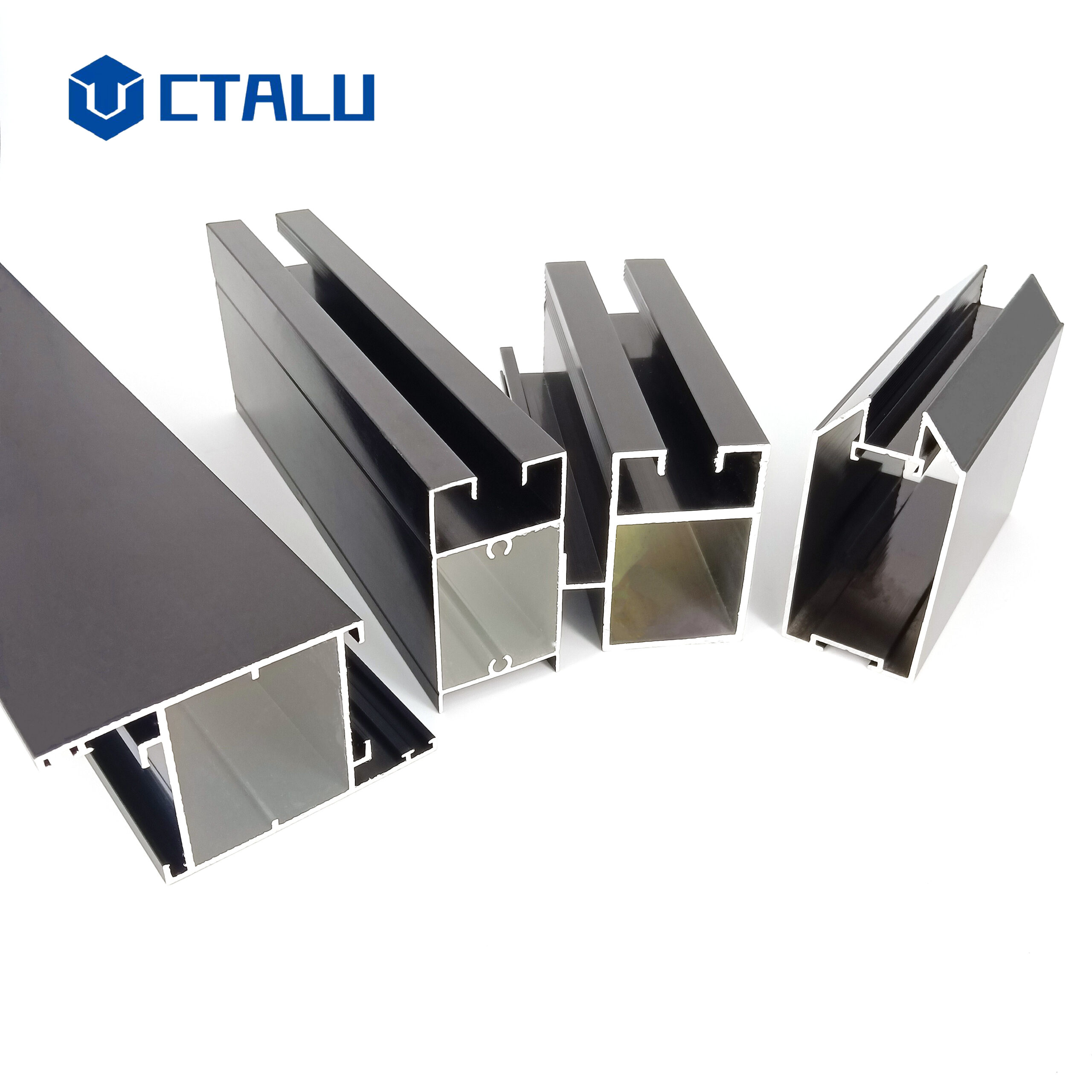

Design & Surface finishing

If you are a wholesaler or distributor of aluminium window and door profiles, you may have several designs for the window or door systems that you purchase from various importers or aluminium factories. In any case, you must select the best-selling items. Then you could send your samples, have the factory design them, and have the drawings confirmed. Obviously, different aluminium factories will charge different fees for digging a new die; you can read our previous post about the factors that influence your purchasing costs.

After you’ve confirmed your design, if the aluminium factory has a complete production line (such as Cheetah Aluminum, which can produce from extrusion to anodizing and powder coating), tell the supplier your specifications and request pricing for the total amount.

-

Thickness & Weight

Typically, thicker aluminium extrusion profiles are much more expensive than thin ones. It is critical to examine the drawings of aluminium profiles and highlight the thickness, as this will influence the final cost of your purchase.

Inquiring about the tolerance of the extruded aluminium is a good way to control the weight. We normally put 10mm in Cheetah Aluminum for customer reference; the final weight will be in this scale.

-

Brand & Packging

The majority of aluminium profile factories in China accept OEM orders. There are various materials used to pack the aluminium profiles:

1, Protective stickers (brand imprinting available)

2, Shrink sleeves

3, Craft paper

4, EPE foam

5, Poly bag

-

Quantities of the order

Most manufacturers frequently offer discounts on large volume purchases as opposed to small volume purchases. If the surface finishing of aluminium profiles in the order is nearly identical, the production time will be significantly reduced. The larger the number of the same item, the faster the production time.

-

Shipping

The transport time will be shorter if your country is closer to China. However, if imported to the Americas or Africa, the transport time and sea cost will be longer.

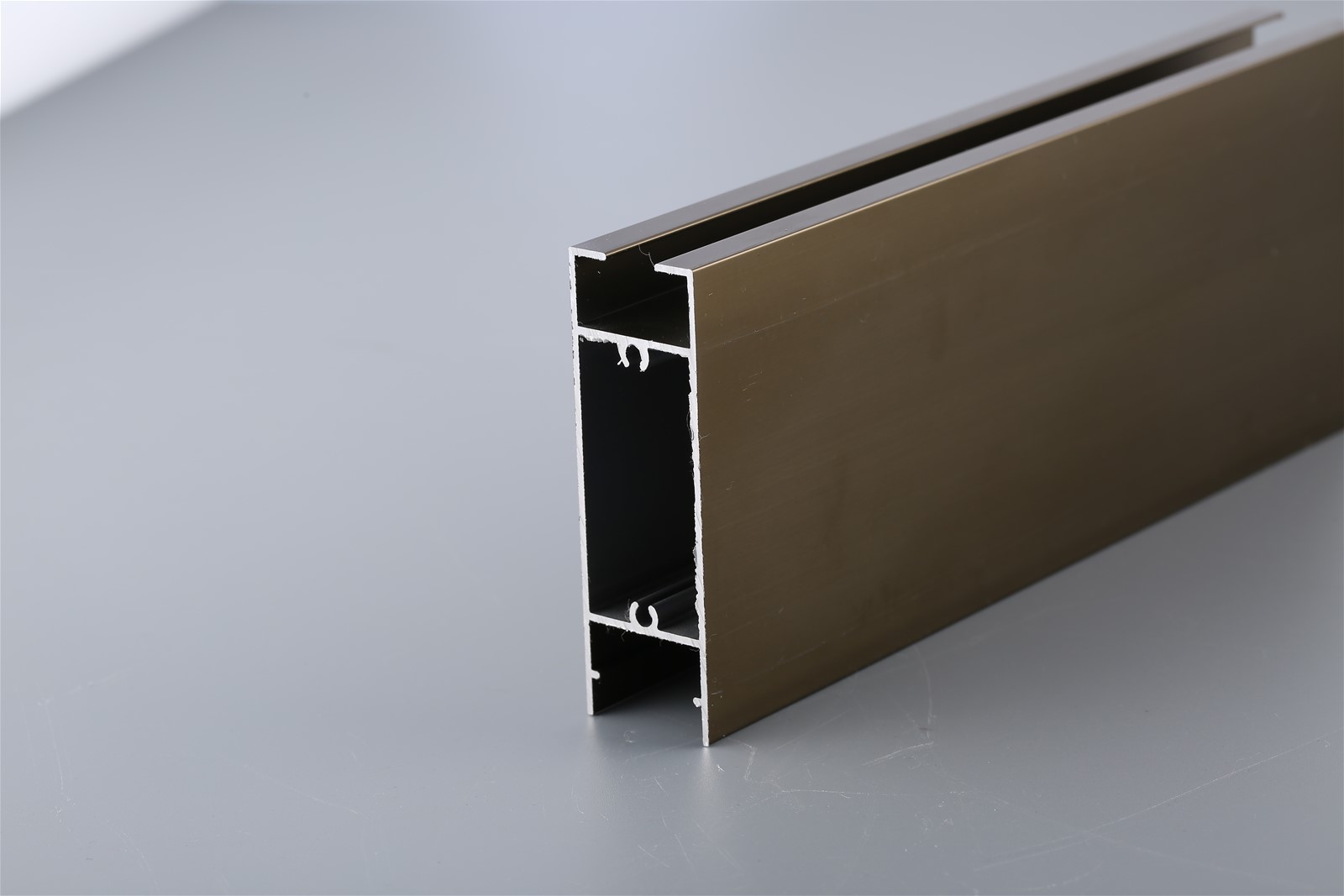

What Is the Distinction Between Mill Finish Aluminium and Anodized Aluminium Profiles?

-

Color

Mill finishing refers to the raw state of aluminium after it has been extruded and hardened to a sufficient hardness. When exposed to air, aluminium profiles that have not been anodized will form a thin oxide film. However, the oxide film offers very little protection. The surface of the aluminium profile will turn black when exposed to wet weather or acid rain.

-

Life Span

Aluminium profiles will have a significantly longer service life after anodizing. The dense oxide film on the surface of the aluminium profile can protect the aluminium profile from acid air attack.

-

Price & Lead time

Anodizing will take longer to produce than mill finishing because it is a separate process after the extrusion of aluminium profiles. Anodizing is also more expensive. The price will be lower if the silver aluminium profile is produced. If the customer requires bronzed or black aluminium profiles, the price will rise.

How To Check the Quality for Doors and Windows Aluminium Profiles?

In fact, the quality of doors and windows is determined not only by the aluminium sections, but also by the accessories and glass. Because Cheetah Aluminum primarily manufactures aluminium profiles, this article focuses solely on the quality of aluminium profiles.

-

Thickness

Cheetah Aluminum manufactures aluminium extrusion profiles in accordance with GB/T14846. The window or door frame is adjustable from 0.8mm to 1.4mm. Too thin aluminium can cause doors and windows to open and close loosely, as well as not withstand strong winds and rain well.

-

Film of Anodizing or powder coating

We need to measure the film layer of aluminium profiles before packaging. A sufficient film thickness can extend the life of an aluminium profile’s surface.

-

Surface inspection

After the aluminium has been extruded, it must be checked for size, hardness, and flatness. A quality inspector is required for each extruder to inspect each aluminium profile. Ensure that the aluminium profile’s surface is flat and smooth.

Cheetah Aluminum has a complete aluminium profile production line, from mill finishing, to any kind of surface treatments, such as anodizing profiles or powder coating profiles, wood grain or electrophoresis.

Any questions please send to us, please feel free to contact:

Wechat / Whatsapp: +86 16603008969

Email: simon@ctalu.com