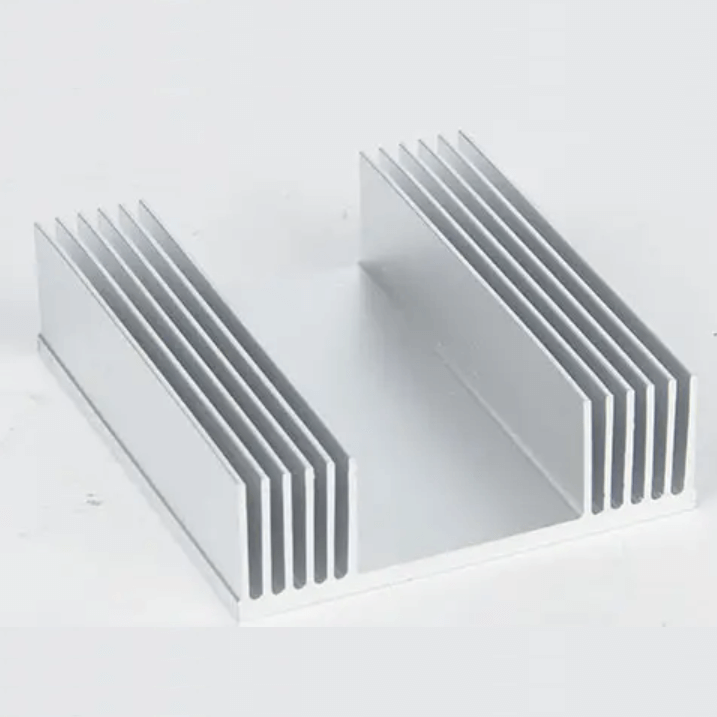

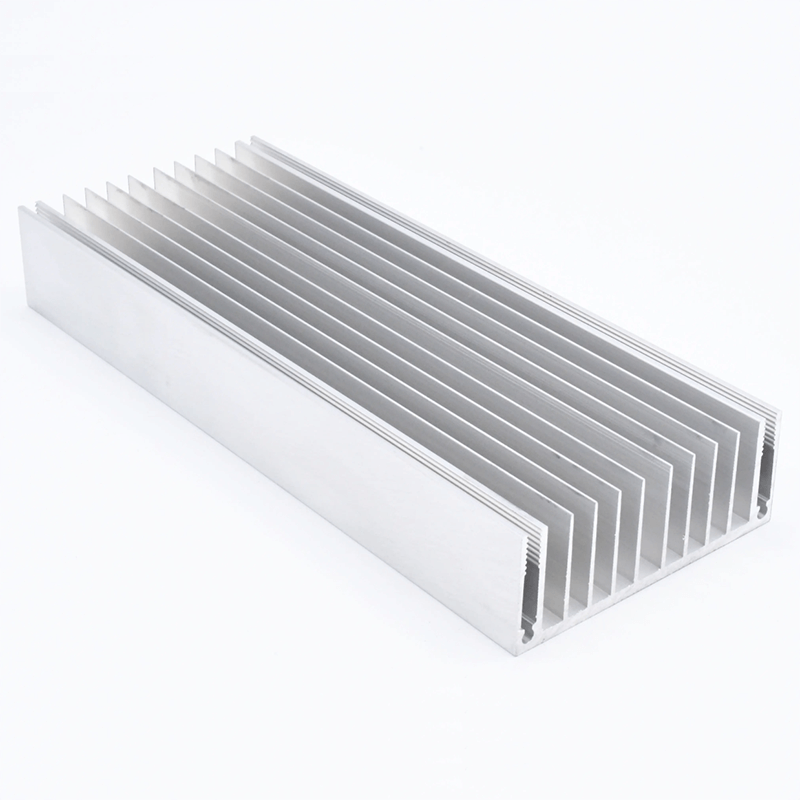

Product description of Heat sink aluminium profile

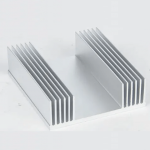

The heat sink has the characteristics of beautiful outline, light , good heat dissipation performance, and energy-saving effect

Surface treatment

anodic oxidation to increase the corrosion resistance, wear-resistance and appearance aesthetics of aluminium

Types

electronic, computer radiator aluminium profiles,

sunflower aluminium profiles, power semiconductor radiator profiles, etc.

Usage

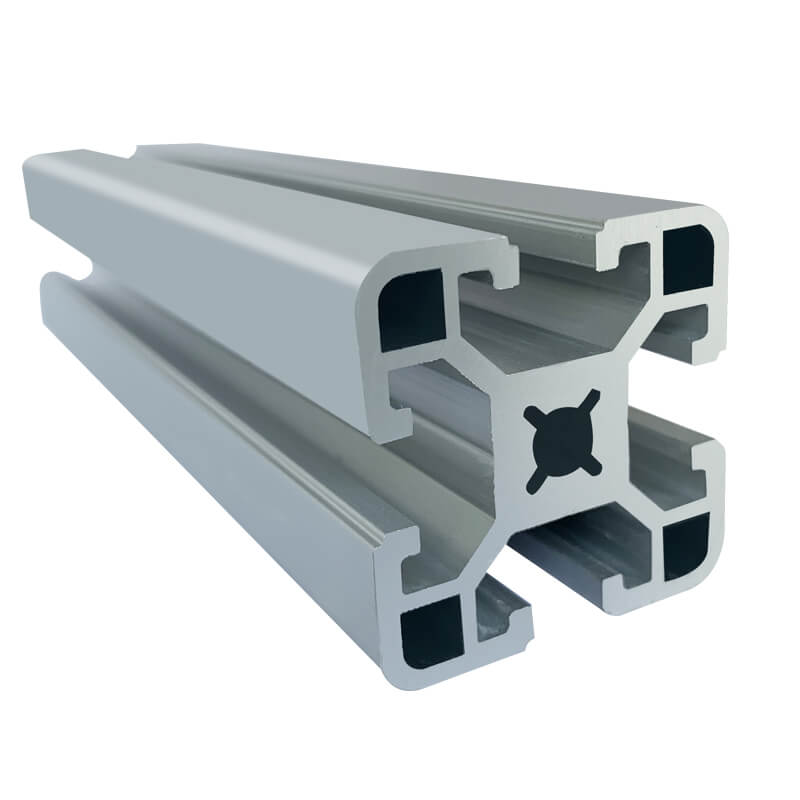

machinery, automobile, wind power generation, engineering machinery,

railway locomotive, household appliances and other industries.

In terms of energy saving, material saving, decoration, price and weight, aluminium profile is the best material for making heat sink.

Suggest

aluminium heat sink includes high-pressure cast aluminium and tensile aluminium alloy welding.

Choose a high-pressure cast aluminium radiator.

- The radiator is die-cast, so there is no weld leakage.

- It advantage is that the product is not limited by the district heating Due to the modular design, it can not be corroded by oxygen even in the open boiler system.

Advantages of Heat sink aluminium profile

Good heat dissipation

The characteristics of energy-saving are very obvious. In the same room, if the radiators of the same specification are used, the number of aluminium castings is less than that of steel.

Good corrosion performance

It has good oxidation resistance without adding any additives. Its principle is that once aluminium encounters oxygen in the air, it will form an oxide film, which is tough and dense to prevent further corrosion.

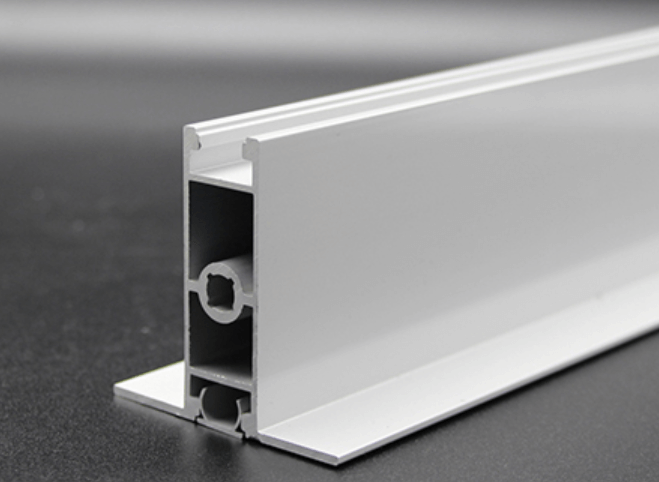

Installation

1. open the package of the aluminium profile radiator and install the vent valve and Union first.

2.draw the position of the special hook hole on the wall according to the installation drawing provided

3.consider the damage to the radiator caused by the expansion and contraction of the heating pipe during installation.

4.put the 12 expansion pipe in and flat.

5.drill 12 holes with an impact drill, and the depth will be flush with the outer wall

6.install the bottom hook and tighten the screws after meeting the requirements.

7.place it on the hook installed at the bottom, install the upper hook, adjust the hook position, and tighten the expansion screw after clamping

8.install the pipe according to the drawing requirements, connect it with the water inlet and outlet, and fasten all parts

9. input hot water, open the air release valve, and release air until water comes out.

10 the oxygen content in the heat medium will not be greater than 0.05g per square meter.