Multiple factors influence the price of aluminum due to the variety and complexity of custom aluminum extrusions. With the advancement of global trading in this world, we are all focusing on “How to save costs from import and export,” but we should actually chop up the purchasing process for aluminum, to dissect the procedure, from zero to hero. In this article, we will introduce readers to various produce processing methods. Or, to put it another way, from production to consumption.

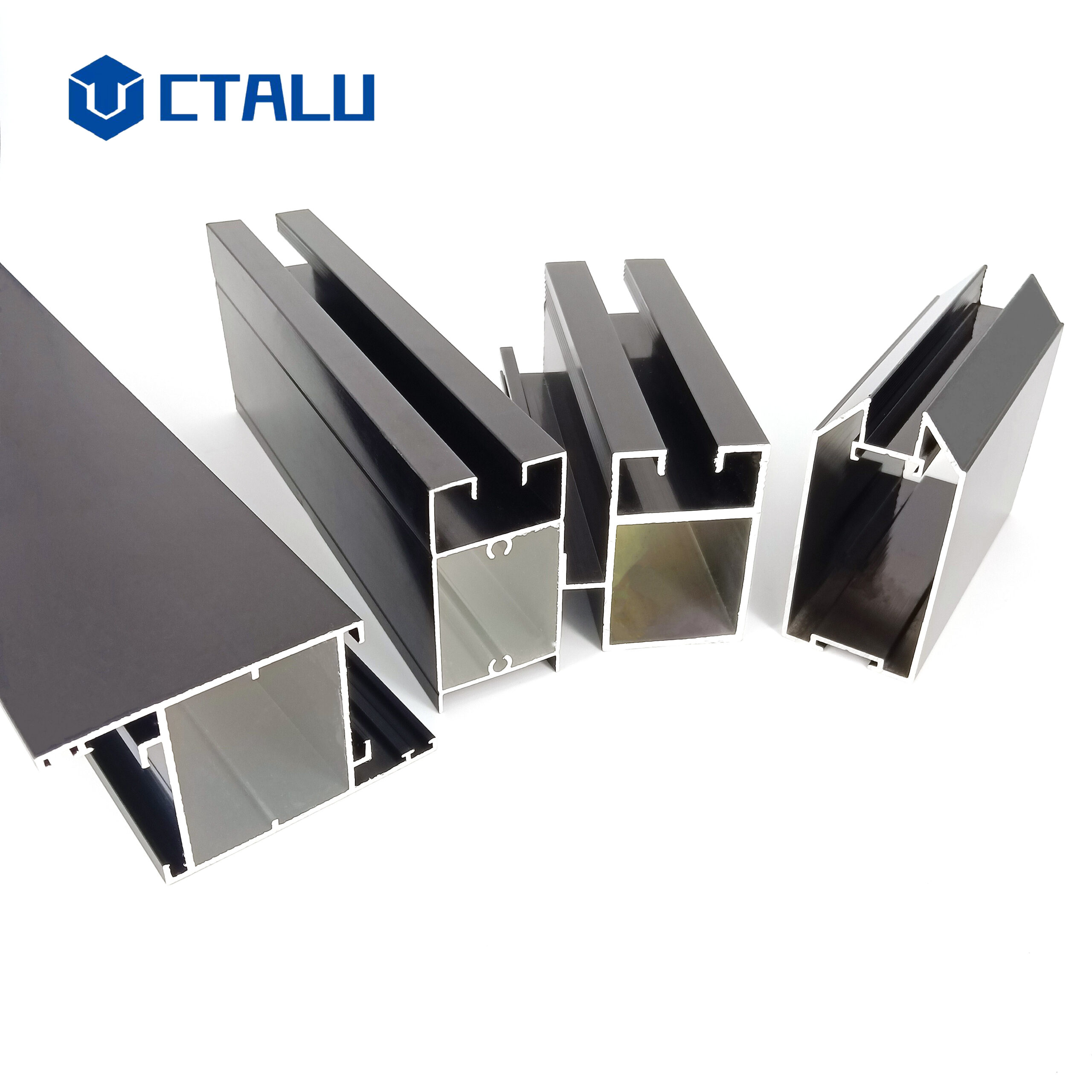

Die cost/ Shapes of aluminum

A complex-shaped die, in general, can be more expansive, not only in the production of aluminum die, but also in the processing of aluminum extrusion. All new dies for custom aluminum profiles must be tailored to the needs of the customer. From the time the customer provides the samples to the time the factory designer creates the drawings, we must double-check the size, weight, thickness, tolerance, and key part (like the position of wool tops, position of vinyl).

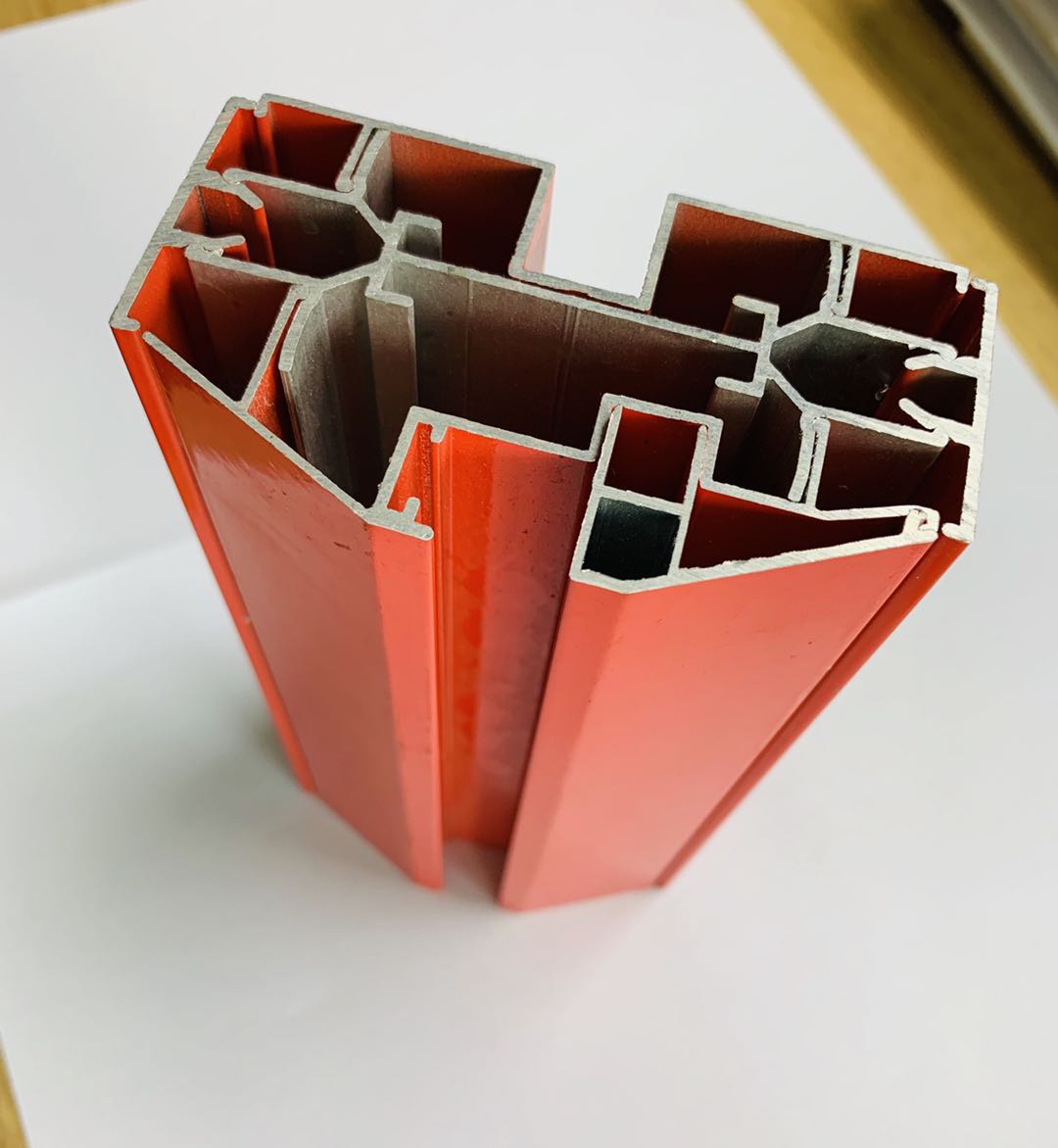

In our production, we choose to use H13 glass hard steel since it increases die land efficiency while also having a significant impact on exit velocity for aluminum profile extrusion. Typically, a die with complex geometries will require more labor and time to build. Geometries with an asymmetry are more intricate than those with a symmetry. The molten aluminum will flow into the die during the aluminum extrusion process, allowing symmetrical dies to receive more evenly distributed supply and pressure. In this instance, we will learn that lock stile is preferable to interlocker while obtaining aluminum liquid supply for the sliding window series.

One important factor in prices is the circumscribed circle diameter (CCD) of the dies. What then is the benchmark? We frequently charge RMB 800 for small molds, clips, and aluminum angles. For example, a 160×60 Flat die costs RMB 800, whereas a 160×120 Divergent die costs RMB 1400, according to the CCD. You can get in touch with our aluminum die department for more details or a price list to get what you need. As a result, the CCD is correlated with the cross-section, the larger the mold, the higher the cost of the die.

The total cost of a die used in standard architectural or standard profiles ranges between RMB 800 and RMB 4000. The cost will rise as the level of complexity rises. T-slot(超链接) is one example of a joining method. Aluminum profiles, such as t-slot, necessitate the production of two or three dies simultaneously. T-slots are used in industrial aluminum framing. It makes sense to use precise equipment to measure the position of nut tracks and snap fits in order to improve connection performance.

The other factor is thickness. With today’s fierce competition, some custom extruded aluminum may request a lighter weight. We are attempting to control the global market demand in order to meet it. In any case, all customized aluminum profiles must satisfy clients. Some markets request that the thickness be less than 0.8mm. This will drastically shorten one’s life span. Why? The force of friction during extrusion processing wears down the die land, causing the discharge hole of the die to grow wider and wider. This die should be discarded as scrap once it has exceeded the thickness specified by the customer.

Raw Aluminum Price

Because we are involved in international trade, we must be concerned with current events in the world. The United States dollar is the world’s primary reserve currency. When the Federal Reserve System raises interest rates, large amounts of money flow into America immediately, and the US dollar appreciates. Then nonferrous metals, such as aluminum, have a chance to fall in value. This is an excellent time to begin purchasing goods such as aluminum extrusions. The first is cheaper raw aluminum, which could be transferred to the margin. On the other hand, holding dollars increases the value of our pocket, which is another advantage.

In a macroscopic perspective, we should also know the policy of a country. the most important factor influencing cost is the electric charge, which is why we are always concerned about the price of coal. Thermal power generation accounted for 70% of total electric quantity. As a result, COAL will have an impact on electricity generation, and electricity will have an impact on the price of raw aluminum.

If you have experience importing aluminum profiles from China, you’ve probably heard of the prices for NH aluminum (also known as Nanhai aluminum price), Changjiang aluminum price, and Shanghai aluminum pricing. However, have you thought about why this price is so different? Can I simply choose the cheapest one to pay the supplier? You can’t, is the response.

The prefix of aluminum price like “NH” means the location. This is the location of spot trading. The price will change everyday following the market. To distinguish the difference of the price, need to understand is relevant to the origin of electrolytic aluminum, distribute in the area of Yangtze River (Changjiang), Shandong province and Guangxi province. Different prices are derived from the freight cost from original location to the trading places.

Secondary operations

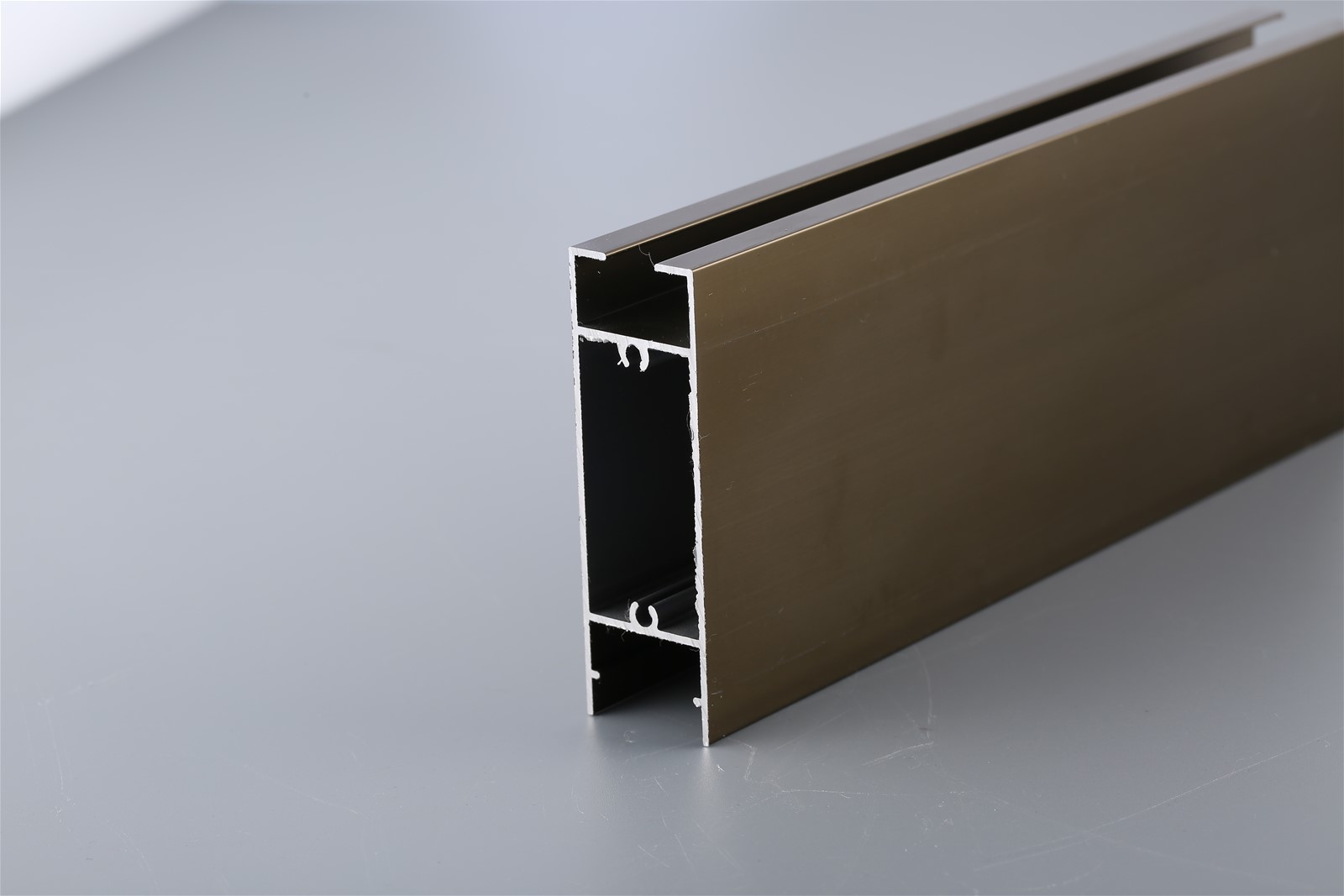

After the aluminum is extruded, it is passed through an aging furnace to increase the hardness of the aluminum to 11-13 WB, and factory workers transfer the profiles to any secondary operations department for anodizing or powder coating finishing.

Anodizing(插入), also known as anodic oxidation, is a process in which aluminum is used as the anode and chemical raw materials are added; after powering up, an oxide film forms on the surface of the aluminum. Because no other color additive is required, pure silver color will be more cost-effective in anodizing. However, if you have a demand for the surface, such as sandblasting, or if you expect the color to be black or bronze, it will give rise to the expenditure.

We can perform electrophoresis extinction in Cheetah Aluminum International Co., Ltd. (插入). This is a technology that comes after electrophoresis. You can learn more about this technology by clicking on the link. This process improves the corrosion resistance and smoothness of the aluminum surface. However, there are always two sides to every coin, and this treatment is more expensive than standard anodizing.

Nowadays, powder coating is the most common treatment. Add a layer of material to the extruded aluminum for protection and improved appearance. To provide an appealing and corrosion-resistant surface, a very durable and hard finish in a wide range of custom colors is created. According to the GB standard in China, the layer of powder coating aluminum should be greater than 40 um, but Cheetah Aluminum will frequently spray it 60-80 um to improve performance.

Packaging of aluminum extrusion profiles

Packaging can be done in a variety of ways. The most common method is to adhere protective films to the surface of aluminum framing, a few pieces per bundle, and then cover with shrink wrap packaging. All patterns can be designed and printed on protective films with the factory’s or the customer’s brand.

Kraft paper is also used in packaging. Some customers requested that our factory pack their orders with kraft paper or composite paper to improve the visual appeal. Indeed, the entire package was improved. Improves waterproofing and protects the surface of aluminum profiles.

There are some factors that influence the costs. For starters, shorter aluminum profiles will increase costs. As labor costs rise, shorter profiles will reduce workers’ income. If the profile is less than 4 meters long, the factory will usually charge an operation fee of about RMB 500 per ton.

What if I want each profile to be packed separately? We appear to be returning to the subject of labor costs. Yes, it is necessary to charge an additional fee for it. Furniture manufacturers would request that all round tube aluminum be packed individually in order to keep the surface smooth and glossy and to prevent scratching.

Logistic cost and Tariffs

Before you begin the process of purchasing aluminum extrusions, you should look for a better logistics company and a trustworthy broker.

For every thousand people, there are a thousand Hamlets. In this market, no one can get the lowest price, and no supplier can quote the lowest price. In this market, we require a comfortable service at a reasonable price. Using a good broker can help you avoid high tariffs from trade barriers. A good relationship with customs is also advantageous to any business.

Traveling by stand-on vessel from a Chinese port to Southeast Asia takes only 5 days. However, according to ocean-going vessels, it takes at least 35-45 days to arrive in Africa or South America. We will have our funds “window period” during this time.

Also, instead of quoting just “FOB” terms, you can ask your supplier to arrange the entire shipping stuffs, using “CIF” price terms to save all these troublesome businesses, all you have to do is double confirm the ocean freight with suppliers. The most important thing for an importer is to pay more attention to the broker for customs clearance. It makes sense to focus on customs news and communicate with the broker to ensure that every container arrives safely at the destination port.

There are still have hundreds of factors, but one tip is that we just need to hold the key factors, control well the crucial elements, so that makes the cost saved, makes the business in skyrocketing sell. We’ll talk about aluminum products and aluminum information in greater detail.

Cheetah Aluminum has a complete aluminum profile production line, from mill finishing, to any kind of surface treatments, such as anodizing profiles or powder coating profiles, wood grain or electrophoresis.

Any questions please send to us, please feel free to contact:

Email: simon@ctalu.com